On the Remington Portable typewriter the typebars rest on the felt strip that edges the lifting table. Over time the typebars make a dent in the felt. Uneven wear over time per typebar leads to the row of type to be out of alignment.

To fix this, new felt was mounted on the lifting table edge. The black felt strip is rounded on the top and clamped by a metal strip on the bottom of the lifting table. To make it nicely rounded on top, the felt is bent double. Because the felt controls the position of the typebars in the raised position and needs to be out of the way in lowered position, the size of the felt matters. It's about 5 by 8 mm when clamped. (The original was folded double, the new felt that was at hand was thinner and folded over twice to get the thickness.)

The felt strip is clamped under the metal strip that is screwed underneath the lifting table. Some small unevenness can be corrected by tugging and tucking the felt under the clamp. The old, original felt in the picture shows the dents made by the typebars.

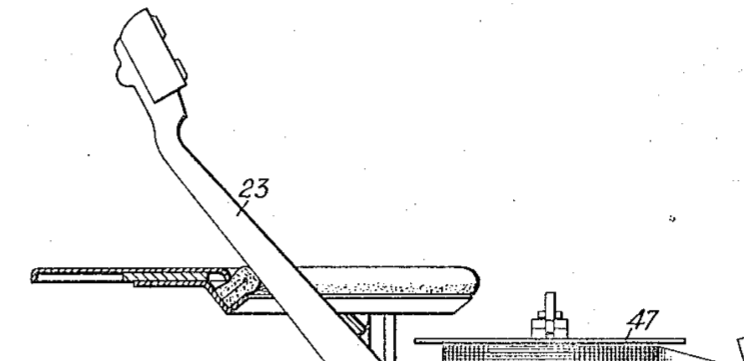

With the new felt mounted and the lifting table back in, the typebars in the lower position lie flat resting on the felt and/or table. Also already mounted in the picture are the housing top and the outer frame. For mounting the lifting table, the housing top should really be removed for access to screws that clamp the lifting table to the lifting arms. (It's tricky enough even then.)

In the raised position, the typebars make an even curve that is approximately horizontal to the machine. (The paint on the lifting table is badly damaged, had a bit of a disaster there as well. So much tension in the paint layer that it just flakes off at the slightest breeze. Now fixed down at the edges, but messy.)

Now with the second attempt at a new felt strip, the typbars are good enough in both positions and can still take some 'settling in'. The left and right-most typebars are hardest to get right and to align nicely with the protecting hooks.

It's getting there. Adjustments next.

To fix this, new felt was mounted on the lifting table edge. The black felt strip is rounded on the top and clamped by a metal strip on the bottom of the lifting table. To make it nicely rounded on top, the felt is bent double. Because the felt controls the position of the typebars in the raised position and needs to be out of the way in lowered position, the size of the felt matters. It's about 5 by 8 mm when clamped. (The original was folded double, the new felt that was at hand was thinner and folded over twice to get the thickness.)

The felt strip is clamped under the metal strip that is screwed underneath the lifting table. Some small unevenness can be corrected by tugging and tucking the felt under the clamp. The old, original felt in the picture shows the dents made by the typebars.

With the new felt mounted and the lifting table back in, the typebars in the lower position lie flat resting on the felt and/or table. Also already mounted in the picture are the housing top and the outer frame. For mounting the lifting table, the housing top should really be removed for access to screws that clamp the lifting table to the lifting arms. (It's tricky enough even then.)

In the raised position, the typebars make an even curve that is approximately horizontal to the machine. (The paint on the lifting table is badly damaged, had a bit of a disaster there as well. So much tension in the paint layer that it just flakes off at the slightest breeze. Now fixed down at the edges, but messy.)

Now with the second attempt at a new felt strip, the typbars are good enough in both positions and can still take some 'settling in'. The left and right-most typebars are hardest to get right and to align nicely with the protecting hooks.

It's getting there. Adjustments next.